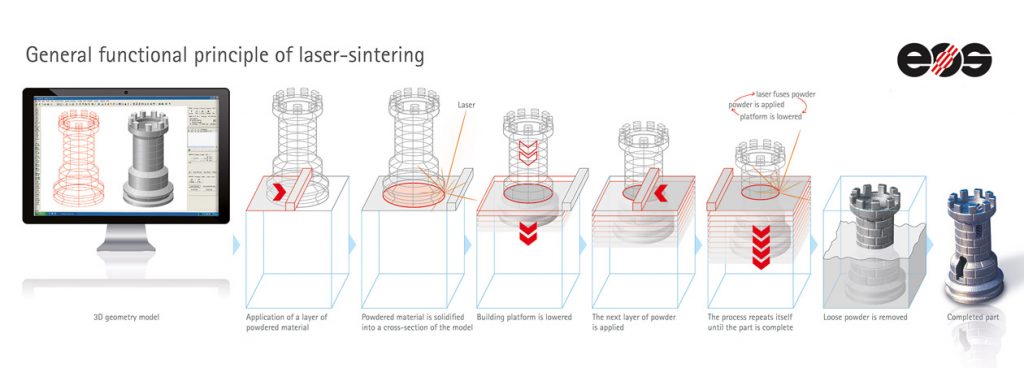

Selective Laser Sintering is a powder based 3D printing process that provides a foundation for industrial level parts with extreme accuracy and durability.

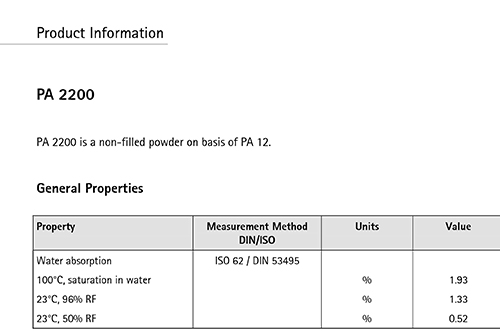

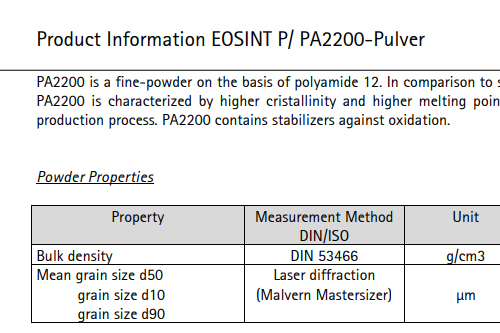

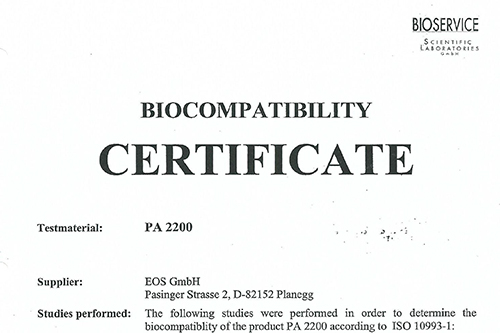

Print without the burden of support material or geometry limitations. Print with some of the most versatile thermoplastics like nylon 12.