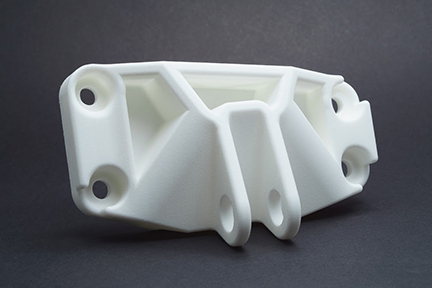

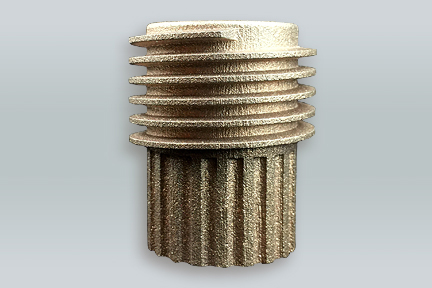

Selective Laser Sintering (SLS)

Material: Nylon 12

- SLS creates strong and flexible parts with high accuracy

- This process can be used for prototypes as well as production end use parts

- Powder based printing allows for ultimate design freedom because no support material is required

- Both small and large parts can be printed in this process

- Price: $

- Turn Around: 1-5 days

- Production Runs: Yes